- Home

- Videos

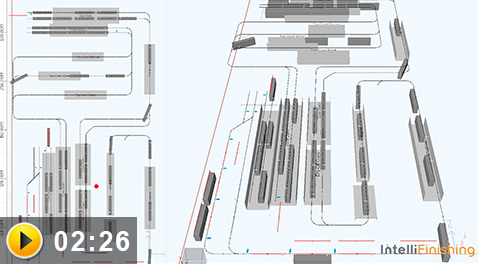

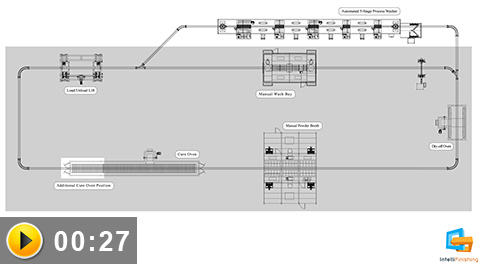

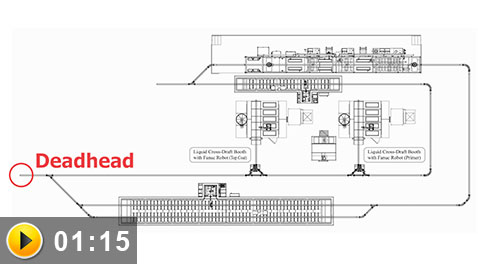

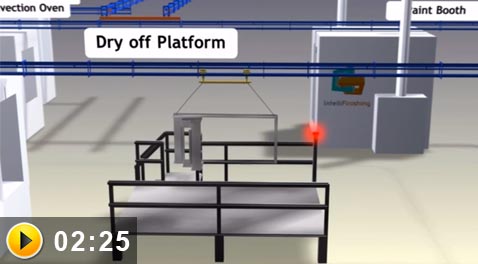

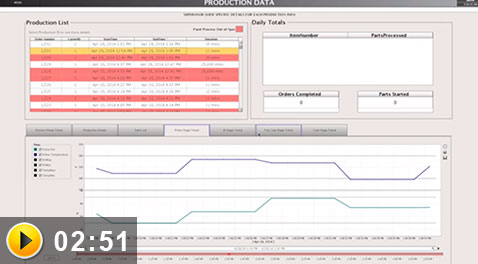

Understanding the IntelliFinishing System

The best way to understand how an IntelliFinishing automated complete finishing system works by viewing our videos, 3D animations, examples and more. The same benefits and features apply to both powder coating and wet paint systems.

Jump to each section:

Complete Systems

View the benefits and features of an IntelliFinishing system through these 3D animations and live footage videos.

Customer Testimonials

You don't have to take our word for it – hear directly from our customers how they feel about their IntelliFinishing systems.

Features

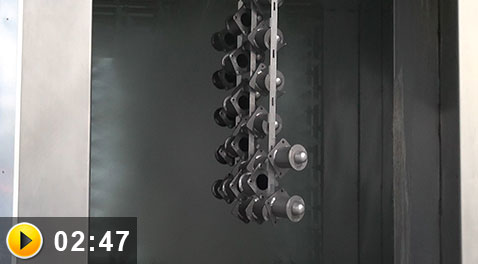

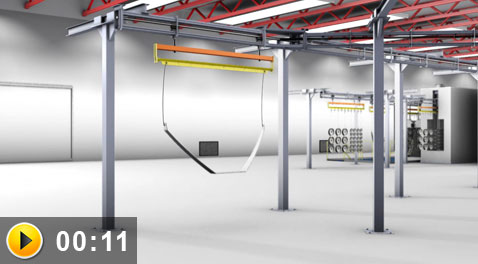

Any of the components featured in these videos can be added to an IntelliFinishing powder coating or wet paint system.

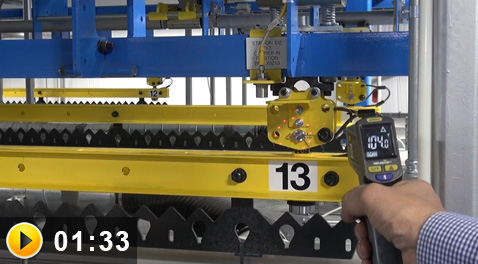

Maintenance & Installation

An IntelliFinishing system requires less maintenance and installed in half the time of traditional power and free or monorail conveyors.