Complete Paint System with Robot Aplication

IntelliFinishing Liquid Paint Systems offer the same flexibility and features of our Powder Coating Systems.

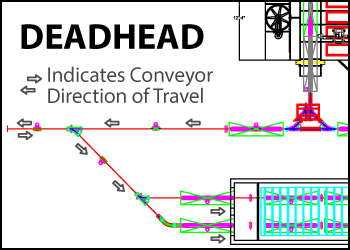

This ultimate flexibility in system layouts is accomplished with the use of deadheads instead of radial turns, plus the ability to reverse from a process, like a paint booth. Features like these can result in more than 20% reduction in equipment costs and floor space savings.

The system runs with a friction-driven rotating tube, not a chain. One of our unique features, that is not available with power and free conveyors or monorail conveyors, is the ability to reverse direction. A deadhead turn, as illustrated, reduces floor space compared to bulb turns. Carriers can stop at any point in the system while the rest of the line continues to move through other processes.

The system runs with a friction-driven rotating tube, not a chain. One of our unique features, that is not available with power and free conveyors or monorail conveyors, is the ability to reverse direction. A deadhead turn, as illustrated, reduces floor space compared to bulb turns. Carriers can stop at any point in the system while the rest of the line continues to move through other processes.

Our modular washers contain separate wash sections that can be programmed independently. For example, a larger part can receive 30 lbs. of pressure for 90 seconds, while a smaller part behind it only receives 20 lbs. of pressure for 45 seconds. As parts exit the wash, air knives blow off excess water preparing each part for the dry-off oven.

IntelliFinishing is an authorized FANUC robot integrator for your fully automated finishing needs. Spinners on each carrier rotate parts inside the paint booth, allowing for a quicker overall process time for your parts and reduces the number of robots required. After exiting the prime coat booth, parts then travel to the top coat booth for final robotic paint application. Each robot paint application is programmable to your part specifications and requirements based on the individual recipe. Larger parts can also be painted consistently and efficiently with the use of a glide switch for reorientation of the part.

Our advanced controls track, monitor, and guide each part through its specific processes for higher quality and lean operation. Our systems are designed to be easily scalable (or even moved) to allow for future expansion, accommodating your high volume needs or processes changes.

We install some of the most energy efficient ovens in the industry, saving as much as 49% in energy costs over non-insulated units. Our ovens, as well as washers, are delivered to your facility in completely modular sections, ready to drop in place for quick installation. With recipe-based smart controls we can stop a carrier in the cure oven for varying cure durations, temperatures, and infrared intensities.

We offer a variety of conveyor models with the ability to handle different weight categories. Contact us to to customize a system to fit your specific needs.