Variable Line Speed in a Complete Finishing System

Unlike traditional chain conveyors that run at one speed, the IntelliFinishing friction-driven conveyor uses multiple drives to allow load bars to move at different speeds. Teamed up with smart controls, this allows you to speed up or slow down within process equipment.

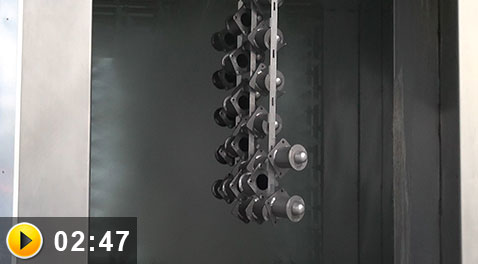

JR Custom Metal Products uses this feature in their shot blast to vary the aggressiveness of the blast. Variable speeds, from 5 feet per minute to 25 feet per minute may be established for each loadbar, and is based on the thickness of the part or the substrate.