The IntelliFinishing Story – IntelliFinishing got it's start by solving a problem for Caterpillar

Stop Chasing the Chain and Maxmize Part Density with an IntelliFinishing System

Coating Systems

Powder coating or liquid paint – same great benefits and advantages.

Conveyor System

Friction-driven (no chain) overhead conveyor moves forward and reverse.

Dry-Off & Cure Ovens

We install the most energy efficient ovens in the industry.

What is IntelliFinishing?

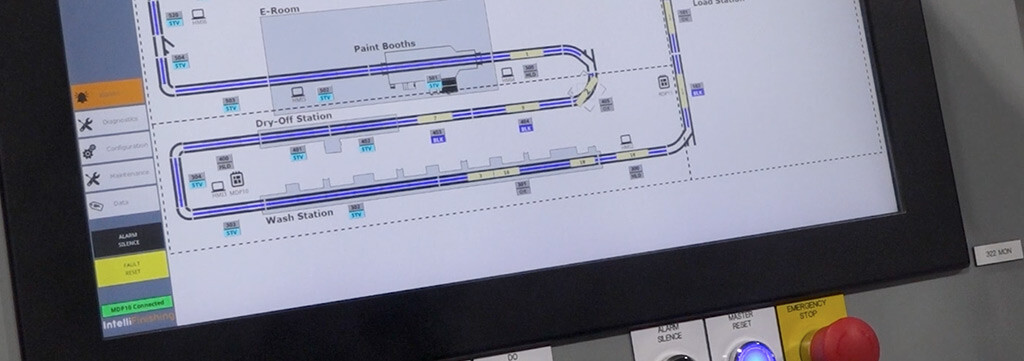

IntelliFinishing is a complete, flexible, conveyorized finishing system (powder coating and liquid paint) provider for manufacturers and custom coaters. Our key differences include the ability to move carriers both forward and backward and our own smart controls technology. Combined, this allows individual sections of the conveyor to move independently, in both speed and direction, throughout the entire system – meaning you can vary the recipe per carrier to process a much wider range of parts. Plus, the friction-driven conveyor decreases the amount of floor space required allowing us to design a system to your specific process requirements.

Endless Layout Possibilities

For your powder coating or liquid paint system IntelliFinishing provides layouts that take advantage of the forward and reverse capabilities of the conveyor along with recipe-based smart controls.

Instead of being stuck with a traditional loop conveyor, we can arrange your system’s components and your process stations to maximize resources, i.e. floorspace, operators, equipment size.

Our system designers work with you to provide layout options you might not even know are possible.