IntelliFinishing is proud to announce the installation of a complete powder coating system for JR Custom Metal Products in Wichita, KS! This system was designed with the flexibility for a variety of part sizes, thicknesses and process times. It includes an optional path to an automated in-line blast system; 4-stage process washer; clean room for powder coating; dual lane split-top cure oven and the ability to easily manage the conveyor, equipment, process and recipes from three centrally located HMI terminals. With our automated powder system and unique conveyor design, no time is wasted in non-value added areas. View the video of this highly flexible and functional powder coating system…and then request a tour.

IntelliFinishing is proud to announce the installation of a complete powder coating system for JR Custom Metal Products in Wichita, KS! This system was designed with the flexibility for a variety of part sizes, thicknesses and process times. It includes an optional path to an automated in-line blast system; 4-stage process washer; clean room for powder coating; dual lane split-top cure oven and the ability to easily manage the conveyor, equipment, process and recipes from three centrally located HMI terminals. With our automated powder system and unique conveyor design, no time is wasted in non-value added areas. View the video of this highly flexible and functional powder coating system…and then request a tour.

VR 360 video tours were a great success at ConExpo in Vegas!

success at ConExpo in Vegas!

If you are interested in a virtual tour of our Complete Automated Finishing System for Industrial Manufacturers, it’s easier than ever before with no travel required.

Visit http://www.intellifinishing.com/contact.html to request a pair of VR glasses that contain a code to scan with your own phone. You can watch and share the complete tour of our latest Powder Coating System project with your company and colleagues! If you are looking for a powder coating system or liquid paint system, you’ll want to see our state-of-the-art friction-driven conveyor technology in action.

Instead of being a specialty item, CARC powder is now an off-the-shelf product.

Read more about it in this interesting article featured in Powder Coated Tough magazine http://bit.ly/2oS7lGF

Adding Part & Data Tracking

Check out this great article in PFOnline – How to Paint a Better Product Using Better Data.

IntelliFinishing adds part and data tracking to its complete paint systems for manufacturers. This allows for the collection of production data which helps drill down to areas that are not running at complete efficiency.

IntelliFinishing powder coating systems or liquid paint systems are automated for increased efficiency, higher quality product and waste minimization. Part and data tracking capabilities are only a part of what our state-of-the-art industrial paint system has to offer our customers.

What Part Does Water Quality Play in Pretreatment?

Water may be the most important component in the pretreatment process. 95% or more of the pretreatment process chemistry is water. It is important to give some thought to water’s contribution in your pretreatment operation.

Water may be the most important component in the pretreatment process. 95% or more of the pretreatment process chemistry is water. It is important to give some thought to water’s contribution in your pretreatment operation.

The primary role of water is to remove chemical/soil residue and contaminants from the work area, providing a contaminant free surface for optimum coating adhesion and performance. Therefore, water quality is critical to achieve your customers specified coating performance standards.

Directly related to your water quality are the impurities or contaminants that your water contains. One major problem area in the pretreatment process is high TDS (total dissolved solids) accumulating in the rinse water, and being deposited on metal parts during rinsing. When the water evaporates, these impurities are left behind. PH balance also needs to be maintained. Generally, the closer the PH is to neutral (7) and the lower the TDS, is when you achieve the best water quality.

Poor water quality results in:

- adhesion failure

- rust

- warranty claims

- excessive water treatment costs

- environmental compliance issues

Good water quality is an extremely important key to your pretreatment process, and should be monitored and controlled routinely, efficiently and effectively.

Congratulations to IntelliFinishing’s Joshua Gilmore for being chosen the Central States Chapter Supplier of the Year!

Joshua was recognized on Tuesday, June 20th at the annual meeting for his support and commitment to his chapter and CCAI. Read more here.

on Tuesday, June 20th at the annual meeting for his support and commitment to his chapter and CCAI. Read more here.

The Chemical Coaters Association International is a technical and professional organization that provides information and training on surface coating technologies. Mulitiple active local chapters across the U.S. serve as excellent forums to discuss regional concerns, as well as connect finishers and suppliers through multiple networking opportunities.

Have you researched the latest advances in pre-treatment, racking strategies and powder formulations? These advances do more than just increase the quality of the parts you deliver to your customers.

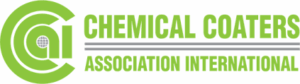

IntelliFinishing complete paint systems for manufacturers offers Lean automated finishing systems that increase your throughput by minimizing line gaps therefore decreasing waiting and transportation waste.

Our distinctive friction-driven (or as we call it, chainless) powder coating or liquid paint conveyor sytem is designed specifically for your manufacturing facility (with your provided specifications) to improve flow with dual lane ovens that optomize cure times with recipes to provide your customers with parts that are cured accurately and consistently every time.

Because it’s not a monument system, our automated paint systems allow for adjustment or expansion to your paint line as new products and processes are introduced!

Did you know that we have tours available? Centrally located in the United States, you can tour a powder coating system that includes a shot-blast spur, or a liquid coating facility to get a visual of what advanced technology can bring to your manufacturing facility. Or you can simply contact us to discuss your automated paint system needs.

Wow! Is the summer moving quickly? Here it is the middle of June and we are finalizing details of our annual educational event. If you haven’t signed up yet, don’t worry, there’s still time.

We have some great guest speakers lined up to educate us all this year at the Midwest Coating Seminar from Akzo Nobel, JR Custom Metal Products and WSU/WATC/NIAR.

We are planning an all day event (with lunch provided on campus) including tours in the morning (for those interested in learning about an automated powder coating system; contact us for details).

The seminar will begin at 10:30 am on September 14th at WATC (Wichita Area Technical College) Main Campus located at 4004 N. Webb Road, Wichita, KS in the Lecture Hall of 300 Building/S Wing.

As always, this is a free educational event for custom metal coaters, metal manufacturers, or anyone interested in learning about current coating technology, processing equipment or chemical pre-treatment options, with lots of easy conversation in a relaxed environment!

There are multiple inexpensive hotel options close to the technical college (on the northeast side of Wichita, Kansas) for our out-of-town attendees. We hope you’ll sign up to attend and join us for some interesting discussions, free food and drinks.

An expert panel will be available at the end of the seminar to answer all of your paint production questions!

Sign up to reserve your seat today at Intellifinishing – a Complete Paint Systems provider and promoter of educational experiences through networking events.

Our friends at JR Custom Metal Products, Inc. of Wichita, KS are featured in Powder Coated Tough magazine this month with our “flexible” alternative to power and free finishing system.

Through extensive research that spanned over five years, the Martinez family learned everything they could about powder coating finishing lines before sealing the deal on an IntelliFinishing Complete Paint System with an in-line shot blast utilizing IntelliFinishing’s smart technology.

Traditional paint systems are limited by line speed. IntelliFinishing load bars are based on part specific recipes with variable line speeds possible at any point in the system. Learn more about IntelliFinishing’s unique line speed here.

Read the Powder Coated Tough article here.

You’ve all heard it. Industry 4.0 has arrived. The buzz is getting louder about the “industrial internet of things” and how automation can enhance production with advanced technology. Our own John Claman has written an article for the Finishing Industry that is featured in the March/April issue of Powder Coated Tough magazine.

You’ve all heard it. Industry 4.0 has arrived. The buzz is getting louder about the “industrial internet of things” and how automation can enhance production with advanced technology. Our own John Claman has written an article for the Finishing Industry that is featured in the March/April issue of Powder Coated Tough magazine.

Check it out to learn more about how embedding computer technology and computer system control in equipment can benefit you. A smart finishing system is within your reach!