- Home

- Videos

- Conveyor Maintenance

- Belt Change

Drive Belt Change on Friction-Driven Conveyor

Changing a drive belt is a simple process. Drive belts should be checked every 6 month for wear. Old belts can be slipped or cut off and new belts installed during breaks or after-hours.

Drive Belt Change Basic Instructions

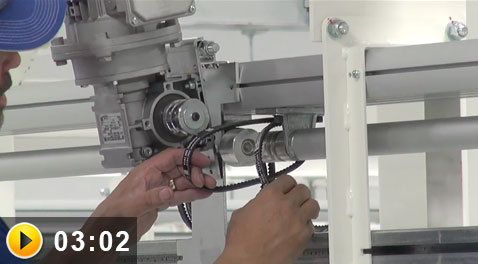

Release the tension on jack screw (back the screw out until the motor mount plate is released and the belts are loose).

Remove the lap joint screw that brings the partable shaft securely together that is located on the partable shaft (drive side) between the belts (requires an allen-wrench).

The lock washer on the back side of the nut is there to make sure that the lap joint screw doesn’t back itself off when the tube is moving.

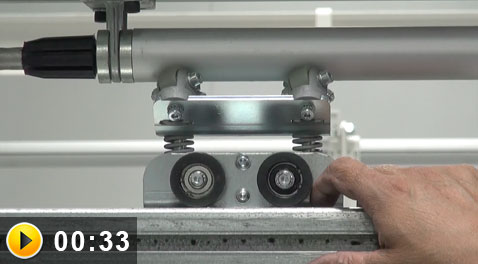

Loosen up the bearing unit bolts on the mounting plate of the bearing unit that is located on each side of the partable shaft.

Be sure not to loosen the bolts (two per plate) so much that they fall out (usually two and one half turns will loosen it enough).

Once all four bolts of the bearing mounting plates are loosened, go back and release each plate (two) by loosening the bolts the rest of the way. This will allow the partable shaft to fall away from where it was connected, enough to allow you to remove the old belts and slip the new belts into position.

Bring the partable shaft assembly back together and tighten the lap joint screw with the allen-wrench.

Move the belts into position on the inside of the mounting plates.

Move the mounting plates back into the up position and tighten the screws by unscrewing slightly and pushing them up until they catch. Once they catch, tighten them up the rest of the way.